|

|

Green Energy Cellulose (Chongqing) Technology Co., Ltd.PHONE:023-62593599 E-MAIL:gecm@sanjiagecm.com URL: www.gecm.com.cn ADD:No. 22, No. 73, Hongguang Avenue, Huaxi Street, Banan District, Chongqing |

|

Sodium Carboxymethyl Cellulose CMC-NaCarboxymethyl cellulose sodium salt product, as the main binder of the negative electrode material of water-based system, is safe, environmentally friendly and inexpensive, and is widely used by domestic and foreign battery manufacturers. The optimal amount of binder can obtain relatively large battery capacity, More cycle life and lower internal resistance. Our company is a manufacturer specializing in lithium battery-grade modified cellulose binders. According to the production process and special performance requirements of the battery industry, the founder has been in-depth exchanges and cooperation with lithium battery companies for more than ten years. Based on advanced production technology, combined with the unique requirements of battery manufacturers for the electrochemical performance of binders, the production process and formula of CMC-Na have been improved and optimized to create a high-purity battery-specific CMC-Na with unique performance advantages. Na product. The role of CMC-Na in batteries: binder, dispersant, thickener, modification. The binder has a great influence on the electrode performance of the battery. A suitable binder can effectively improve the overall performance of the electrode, ensure consistent contact between the active material, the conductive agent and the current collector, and improve the integrity, stability and bonding strength of the electrode. . As a binder, CMC-Na can be widely used in different types of electrode materials to ensure excellent coating processability of electrode slurry, complete and uniform coating, and at the same time, battery capacity, cycle stability and cycle life can be obtained. promote. CMC-Na also has the function of dispersing agent, which can make the active material and the electrolyte form a stable and evenly dispersed paste, so that the electrolyte can be evenly maintained around the active material particles, and ensure that the surface of the active material particles has a uniform, uniform, and uniform surface when the battery is discharged. Sufficient electrolyte coverage while preventing slurry settling. In addition, it can promote the contact between the active material particles and between the active material and the current collector, and improve the occurrence of abnormal voltage drop when the battery is subjected to vibration and in use. The specific roles of CMC-Na in batteries are as follows: 1. The electrode active material, the conductive agent and the current collector are better bonded, and the bonding strength is good 2. In the process of slurry beating, it has good dispersibility and thickening to prevent the slurry from settling. 3. It can improve the absorption rate of the electrolyte and reduce the internal resistance of the battery 4. Better thermal stability improves battery cycle stability and cycle life 5. It can buffer the volume expansion/contraction phenomenon during the charging and discharging process of the battery In addition to the above, our company's slurry process CMC-Na products also have some unique properties, which have been repeatedly verified by more than 40 battery companies, and have obtained many complete comparison data summaries:

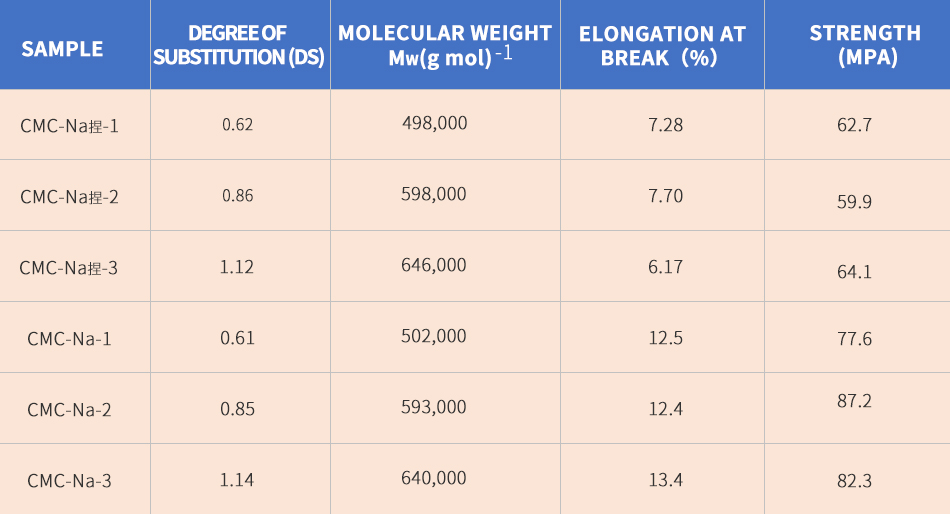

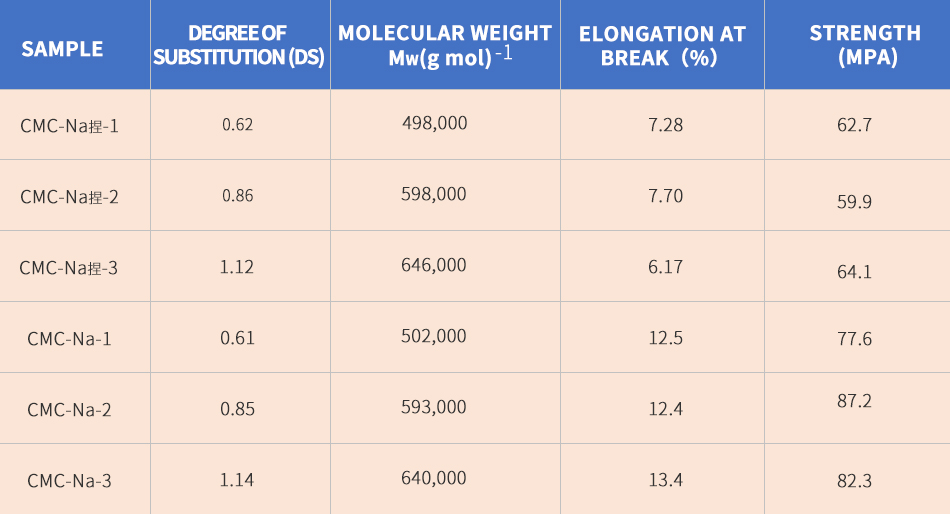

Slurry method CMC-Na is superior to the kneader method CMC-Na product in some performances, and the practical data comparison also confirms that the processing performance will be better.

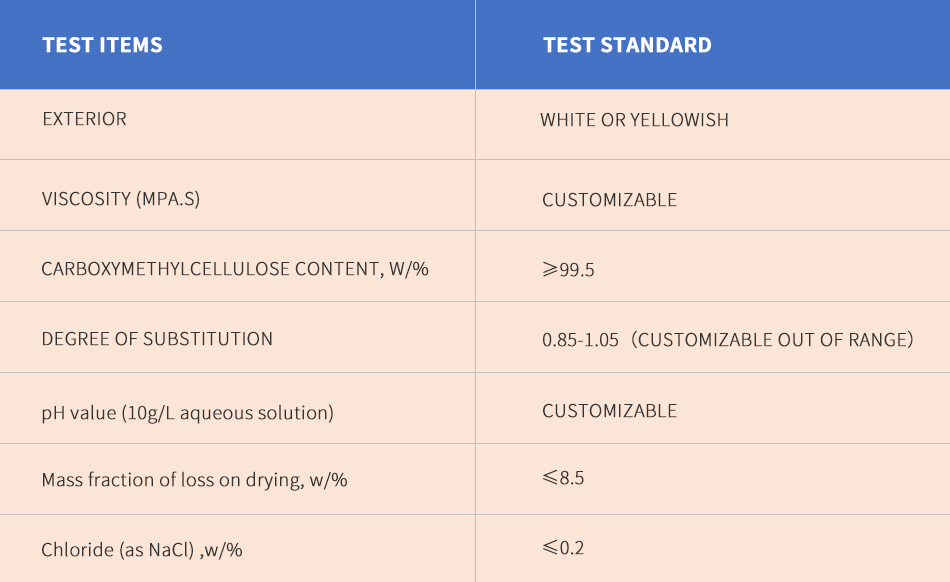

Physical and chemical indicators:

How to use: Sodium carboxymethyl cellulose is a water-soluble binder, which is easy to absorb moisture; at the same time, since the dissolving process of the polymer powder is to absorb water and swell before dissolving, please add it gradually or in batches during stirring and dissolving. into the solvent, otherwise the dissolution efficiency will be affected. Storage conditions: Store in a dry environment away from light Place of Origin: Chongqing

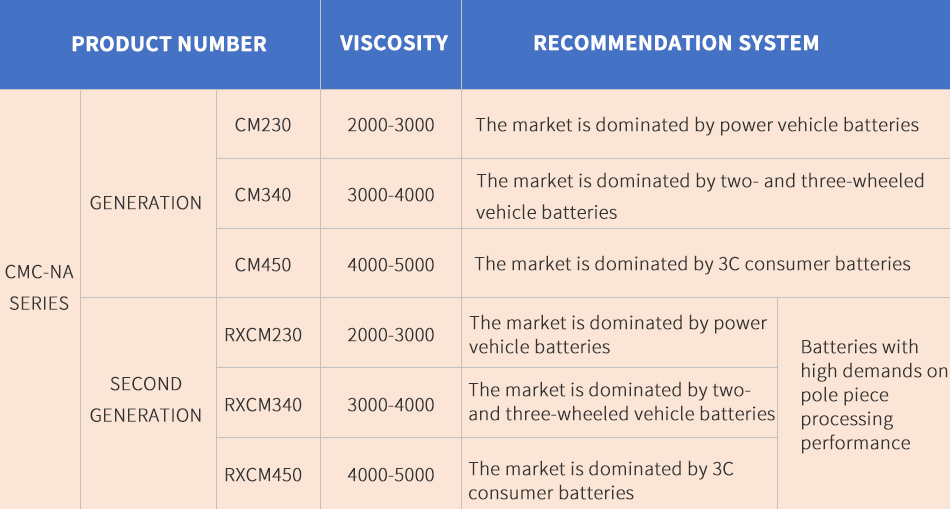

Remarks: Other unconventional viscosity models can be customized Welcome all battery companies and friends from the same industry to negotiate, consult and exchange! |