|

Green Energy Cellulose (Chongqing) Technology Co., Ltd.PHONE:023-62593599 E-MAIL:gecm@sanjiagecm.com URL: www.gecm.com.cn ADD:No. 22, No. 73, Hongguang Avenue, Huaxi Street, Banan District, Chongqing |

|

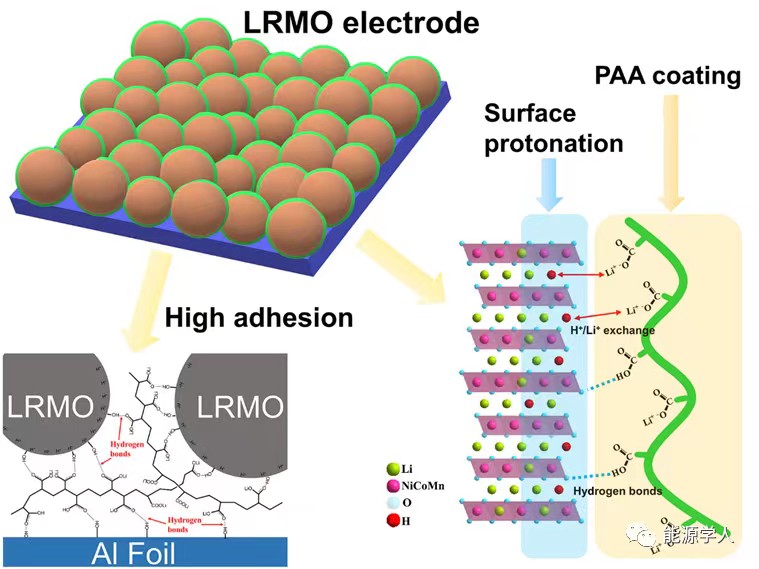

PAAAs an important part of the electrode, the binder plays an important role in stabilizing the anode structure and improving the performance of the battery. According to the research of Zhao Taolin et al., binders with different properties will directly affect the specific capacity, coulombic efficiency and stability of electrochemical properties of the battery. Environmentally friendly and green water-based binders are the mainstream of development, and PAA is more suitable for silicon-based anode materials. According to the research of Li Yanliang et al., most of the binders currently used in the anode are water-based binders, including PAA, CMC, SBR, etc., which have the advantages of solvent-free release, green production environment, low cost, non-flammable, and safe use. According to the research of Zhou Jianhua, Xu Zhengshuai, Mi Jifu, Wu Zhaohui, Li Yanliang and others, PAA has the characteristics of high concentration of carboxyl functional groups, sodium can improve the performance of SEI film to prevent the decomposition of electrolyte during electrochemical cycling, amorphous polymer crystal structure, and increase the first coulombic efficiency of pure silicon electrode to more than 90%, making PAA more suitable for silicon-based anode materials than other binders.

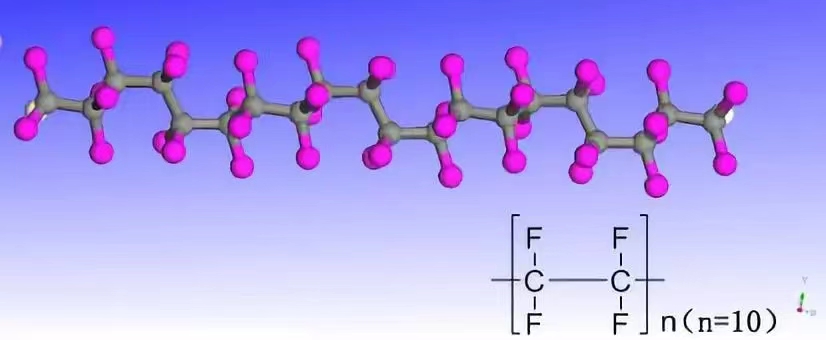

Polyacrylic acid (PAA) is a water-based adhesive for chain polymers. PAA as a binder has the following advantages: A: There is almost no swelling in the electrolyte carbonate solvent, and the electrode structure is stable during charging and discharging; B: The carboxyl content in its structure is higher than that of CMC, which can form strong hydrogen bonds with active materials containing hydroxyl groups and other groups on the surface, and promote the formation of a more uniform coating on the surface of the electrode than CMC. C: It can form a dense film in the electrode sheet, which increases the electrical contact between the active substance and the current collector; D: Excellent tensile mechanical strength, which is conducive to machining. Wening et al. compared the effects of PAA, CMC and PVDF as binders on the performance of lithium titanate electrodes. It was found that the lithium titanate electrodes using PAA showed the best uniformity and good electrochemical performance, with a specific capacity of 150mAh/g when charging and discharging at 1C and 130mAh/g at 16C. PAA is also suitable for lithium iron phosphate cathode and silicon anode. The neutralization of -COOH in PAA greatly affects its performance as a binder. After PAA is dissolved in water, it is easy to form a structure of intermolecular agglomeration due to the strong intermolecular carboxyl-hydrogen bonding force. PAH-M salts were prepared by neutralizing PAA with alkalis, and the electrostatic repulsion between the carboxyl salt groups improved the stretch of the molecular chains, which was conducive to reducing the intermolecular agglomeration effect. Han et al. used different types of PAH-M (M=Li, Na, K, NH4) as binders for silicon/graphite composite anode material electrodes, and studied the effects of salt types and neutralization on the performance of electrodes. The silicon-graphite electrode sheet using PAH0.2Na0.8 exhibited the highest first-time coulombic efficiency (69%), the highest first-time reversible capacity (1400mAh/g), and the best cycling performance. This may be due to the fact that Na+ is beneficial to improve the performance of the SEI film on the surface of the material, thereby improving the kinetic parameters of the lithium intercalation of the material.

|