|

Green Energy Cellulose (Chongqing) Technology Co., Ltd.PHONE:023-62593599 E-MAIL:gecm@sanjiagecm.com URL: www.gecm.com.cn ADD:No. 22, No. 73, Hongguang Avenue, Huaxi Street, Banan District, Chongqing |

|

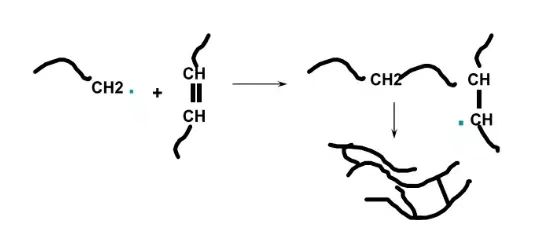

SBRSBR for lithium battery is a styrene-butadiene emulsion, water-based binder, which is generated by emulsion polymerization and copolymerization of styrene and butadiene monomers with water as medium and emulsifier initiator, etc., and the state is an aqueous emulsion with a solid content of about 50%. The SBR latex particle unit is a core-shell structure, and the shell is a cross-linked structure of copolymer molecular chains, and the shell is a hydrophilic polar group and surfactant, so the oily styrene and butadiene polymers can be stably present in water. SBR is a hydrophilic and lipophilic substance. The water-based group is combined with the foil surface group to form a cohesive force, which is conducive to dispersion and slurry stability. The oily segments are combined with the negative electrode graphite to form a cohesive force, so as to achieve the effect of bonding.

Some important parameters of SBR

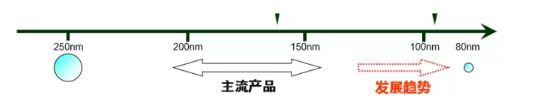

Particle size: With the same amount of addition, the small particle size determines that the contact point between the binder and the active substance increases, so it can have higher adhesion. The consistency of particle size distribution is also a criterion for judging whether SBR is good or bad. Cross-linking: It is divided into high cross-linking and low cross-linking SBR, high cross-linking, slow film formation, strong cohesion, low elongation, and low cross-linking is just the opposite.

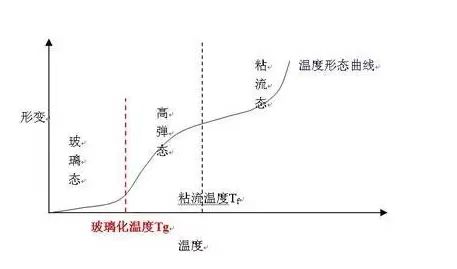

Tg temperature: SBR glass transition temperature is the temperature from high elastic state to glass state, Tg high indicates that the material is relatively not resistant to low temperature, and the appropriately low Tg temperature for lithium battery is conducive to the low temperature performance of the battery, of course, this single factor is not an absolute factor. The synthetic monomers S-styrene and B-butadiene, respectively called S-hard monomer and B-soft monomer, have Tg temperatures of 100 °C and -50 °C, respectively, and the Tg temperature of SBR is adjusted by controlling the different proportions of the two.

Suction performance: including liquid absorption capacity and liquid absorption swelling performance, a good SBR should have a balance between good liquid absorption performance and smaller swelling performance.

Elongation: This is related to the elasticity of SBR, which can return to its initial state after elongation like a spring, and now Si anode materials have higher requirements for this.

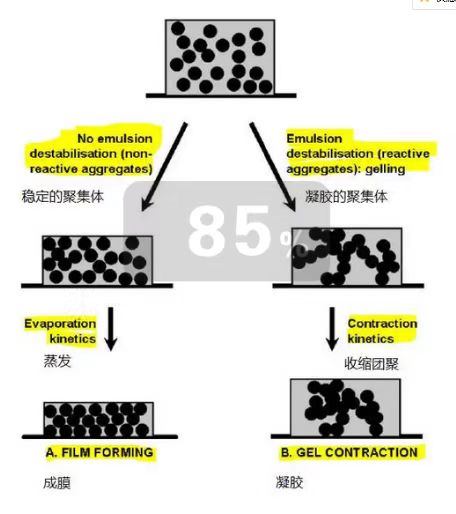

Film-forming process: divided into stable state and unstable state, as shown in the figure below

|